Plastic injection molding

- Home

- Plastic injection molding

The Most Widespread Plastic Processing Method

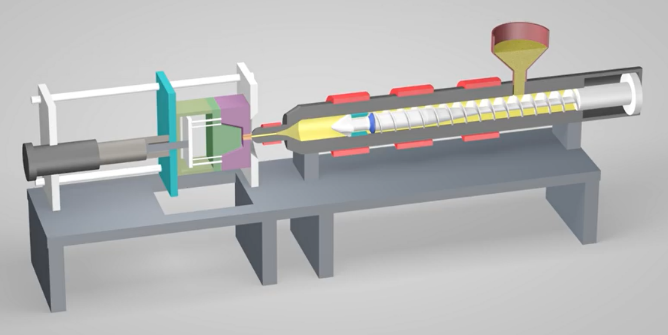

Plastic injection molding is a manufacturing process for producing parts by injecting molten plastic material into a mold. The plastic injection molding technology is used to produce a wide variety of plastic parts, from the smallest components to car door panels and bumpers.

American inventor John Wesley Hyatt, together with his brother Isaiah, patented the first injection molding machine in 1872.

Plastic injection molding is used by many companies to manufacture goods such as packaging, automotive parts and components, toys, storage containers, mechanical parts, and many other plastic products.

Process Steps

- Designing the part and manufacturing the mold from steel or aluminum.

- Feeding plastic material into the hopper.

- Melting and mixing the plastic using a rotating screw.

- Injecting the molten plastic into the mold cavity, where it cools and solidifies into the desired shape.

Advantages

- Transition from aluminum/metal to plastic.

- Production of a large number of identical parts.

- Plastic is lighter than aluminum/metal.

Disadvantages

- Not all metal/aluminum parts can be replaced with plastic.

- Environmental impact.

- High investment cost for purchasing equipment.

Application Examples

The wide range of applications where injection-molded plastic parts can be used makes this technology the most commonly used modern method for manufacturing plastic components.

Plastic injection molding is the ideal solution for producing large volumes of identical parts; today, a plastic injection mold can produce over 1 million cycles.

Transform your idea into reality

From concept to production - the ELJ Automotive team helps you achieve your goals